How important is the efficiency of e-fuels?

In almost no other area of our everyday’s live the courses of action against climate change are debated as intensive as in the field of the mobility. The last decade has been characterized by political actions in favor of electric mobility. Other climate friendly forms of mobility have not been covered in public discussions. However with passing time it becomes obvious that the sole use of electric vehicles will most likely not be the final solution as this technology comes with certain limitations and challenges as well.

A heated argument about solid facts

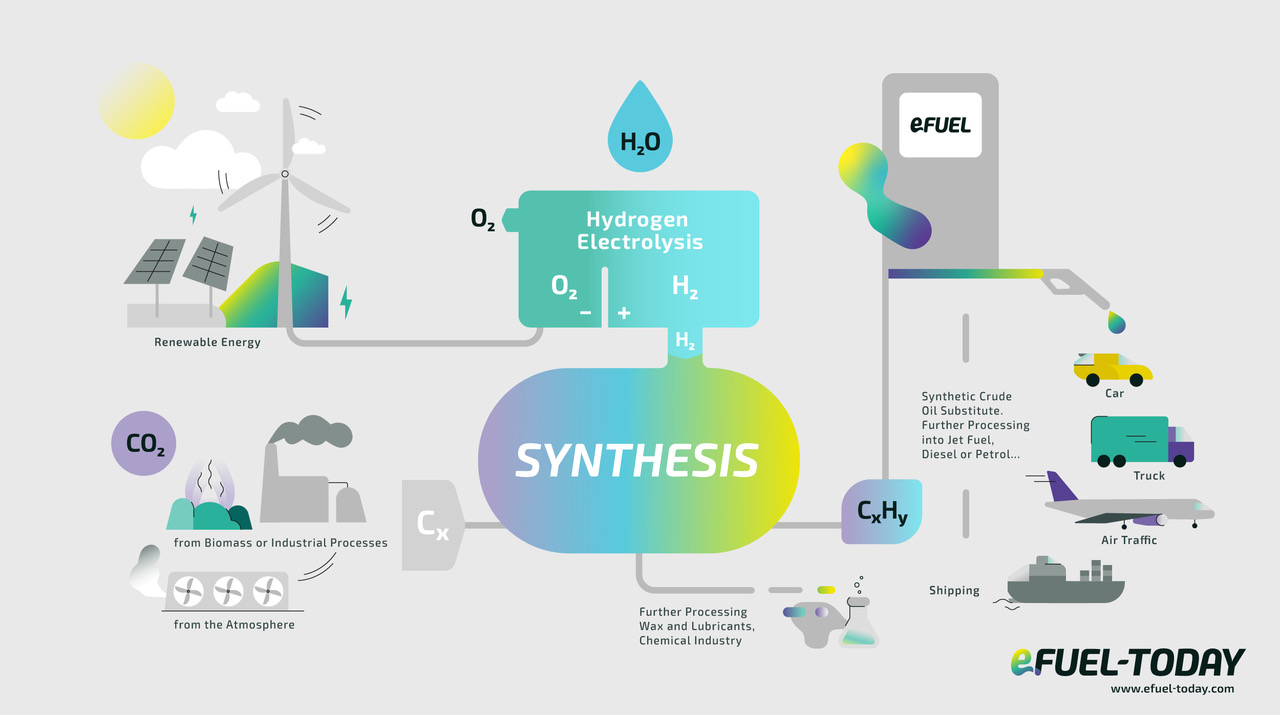

As a result the public debate is widening step by step towards including possible alternatives of BEVs. In this context e-fuels are one of the best methods to include the existing fleet of cars, trucks, planes and ships into our efforts to protect the climate.

However as soon as we speak about e-fuels a heated debate about efficiency is sparked. It’s our aim to hook in here and to show when this debate is legit and under which assumptions a factual and correct argumentation can be found. We want to give insights into a topic which is far more complex than one would assume regarding the clear steps of the policy leaders in favor of electric mobility.

Why the efficiency is just one part of the truth

First of all it has to be pointed put that certain areas of transportation, such as the aviation or shipping industry, cannot be replaced by electric alternatives. Experts agree that due to physical limits these sectors just simply can not be electrified in medium term which means that there is no other alternative than e-fuels in order to achieve carbon neutrality of the aviation and shipping industry. Looking at these sectors it makes no sense to debate the efficiency of e-fuels at all due to a lack of alternatives. These forms of transportation are without ay doubt necessary for todays society but given the ambitious „fit for 55“ goals of the EU we can not make an exception to decarbonize within these industries.

Looking at other forms of mobility, such as the individual transport via cars and trucks, a comparison of the efficiencies of different drive train technologies is legit. However the correct measures have to be identified with great attention and care. To achieve a factual and universal classification the correct methods to rate the efficiency have to be chosen. It is important not to make the mistake to take exclusively the drive train technology or the energy source into account. Other questions such as the source of power or the life cycle of a technology have to compared as well.

The efficiency in the production of e-fuels is a frequently cited argument in direct comparison to e-mobility. But is efficiency the right criterion at all?

Another important aspect is the local structure of energy supply. Looking at Germany for example it is easy to determine that Germany is a country dependent on energy imports. The national production capacity of renewable energy will just not be big enough to cover the needs. Since energy has to be brought into the country from places far away the question has to be addressed if wired energy is sufficient.

What are the methods to rate the ecological footprint of a car?

The ecological footprint of a car is influenced by a variety of different factors. Simplified the contemplation needs to cover the two aspects of the energy source as well as the means of transportation – in this case the car itself.

A rather complex approach to get to the bottom of the efficiency on the side of the source of energy is the „well-to-wheel-approach“. This is method to rate the environmental impact of an energy source during its complete life cycle. This includes all the energy consumption as well as the emissions during the complete lifespan of an energy source starting at the extraction of the raw materials and ending at the usage. The well-to-wheel-approach is again divided into two components: well-to-tank and tank-to-wheel. While the well-to-tank-approach covers the efficiency during the production of a source of energy the tank-to-wheel-approach is analyzing the use of energy in a vehicle.

Another important approach when talking about the efficiency of mobility alternatives is the cradle-to-grave concept. It has been developed to evaluate the environmental influences over the complete lifecycle of a product. This includes the highly relevant aspects of the extraction of raw materials, the production of the vehicle as well as the scrapping of the car after its usage. This approach is exclusively linked to the product level of a mobility alternative without looking at the potentially different energy sources used to power a car.

Well-to-Wheel-Approach: Internal Combustion Engine (ICE) with E-Fuels vs. Battery Electric Vehicle (BEV)

The well-to-wheel-approach evaluates the efficiency of one source of energy in two steps. At first the generation of energy „well-to-tank“ is analyzed.

Looking at the well-to-tank-approach it seems obvious that a higher percentage of the generated energy can be put in a tank if a battery is charged directly and chemical conversion processes during the production of a e-fuel can be skipped. One important aspect that in this case is not taken into account is that the electrical energy needed to charge a battery can not be transported over long distances without severe losses. One of the main disadvantages of wired energy is that it has to be used quite close to where it has been produced.

By using an e-fuel electrical energy sourced from regions far away can be stored without losses and transported over long distances very easily. This way regions of the world rich of renewable energy are able to deliver the power to fuel a car in countries with a comparable lower potential of renewable energy such as Germany.

That the different geographical conditions to produce renewable energy are relevant can be shown by a simple fact: if wind energy is produced in Germany the complete production unit has an efficiency of 18%. An identical production unit placed in a much windier area such as Chile achieves a total efficiency of roughly 74%. Unfortunately this large energy potential can not be charged directly into an electric vehicle all around the globe but it hast to be converted into a chemical source of energy in order to be used over such long distances.

If we stick to our example of the windmill in Germany which is converting 18% of the potential wind energy into renewable electrical energy we have to face further losses leading back to the local power grid and charging infrastructure wich means that in the end 15,2% of the energy can be charged into the „tank“ of an electric vehicle. In a well-to-tank-approach this is our final efficiency for an electric vehicle fueled with renewable energy produced in Germany.

If this now is compared to renewable energy from a Region like Chile we start with an efficiency of the windmill of 74% and over the chemical conversion process during the production of an efuel, the transport all around the world, the refinery process and the distribution process to bring the e-fuel to the local gas station left 35,9% of the potential wind energy in the tank of a car in Germany with an internal combustion engine powered by an e-fuel.

In conclusion in a well-to-tank-approach e-fuels are ahead of a BEV due to the higher yield of renewable energy that ultimately ends up in the car. This is achieved through a more efficient location of the production plant to gain renewable energy.

To get a complete image we have to take a look at the tank-to-wheel-approach afterwards. This is where the electric vehicles are playing their trump card. With an efficiency of up to 82% of the electrical engine itself a very high amount of the stored energy in the battery is transformed into motion. A comparable internal combustion engine only has an efficiency of roughly 35% since we have more losses in other forms of energy than motion such as heat for example.

In a debate about efficiency it is often this crucial tank-to-wheel-approach taken by the supporters of battery electric vehicles to show a supposedly advantage. However if both approaches are brought together to a full well-to-wheel analysis it shows that the initial advantage of a generation of energy in richer regions leads to an almost even level of efficiency.

The well-to-tank consideration ignores the fact that the electricity that is charged directly into a BEV cannot be transported over long distances without losses and that electricity from the respective local grid is therefore dependent.

In conclusion a clear efficiency advantage in favor of one drive train technology can not be identified using the well-to-wheel-approach.

Another study is replacing the wind energy from Chile with solar power from Africa to produce e-fuels. In this case the efficiency of the renewable energy produced in Africa is significantly lower than the energy produced in Chile. However even under these worse circumstances the total well-to-whee definition of efficiency testifies e-fuels a disadvantage of the efficiency compared to a BEW by the factor of 1,7. This differs drastically from the numbers that supporters of BEV are claiming by estimating the advantage of an electric car towards five to seven times compared to an internal combustion engine used with e-fuels. In total this study testifies a total efficiency of 77% for an electric car in Germany and an efficiency of 46% for an internal combustion engine fueled with e-fuels made from solar power in Africa.

Cradle-to-Grave-Approach: Internal Combustion Engine with E-Fuels vs. Battery Electric Vehicle

While the well-to-wheel-approach focuses on the source of energy an important link is missing here. In order to create a holistic view on sustainability and efficiency the impact on the environment during the production process and the scrapping of a vehicle hast to be taken into account as well. The so called cradle-to-grave-approach is doing just that.

Studies have shown that the production of a middle class BEV is producing roughly 15,3 tons of carbon dioxide while the production of a comparable car with an internal combustion engine is producing 10 tons of CO2. In the process of recycling electric vehicles are responsible for significantly more carbon dioxide. In this phase a normal combustion car is producing 1,8 tons while the scrapping of a BEV is responsible for 2,4 tons of CO2.

If the cradle-to-grave-approach is included into the comparison of efficiencies it shows that if a BEV is charged with the German energy mix, which dos not only consists of renewable energy but other forms of energy such as coal as well, it takes a lifespan of roughly 200.000 km until a BEV is more sustainable than a comparable combustion car. Given the rather quick development in technology and rapid model changes it is questionable if the majority of BEVs are on the road long enough to really play their advantage. In conclusion we can say that this second approach to measure efficiency does not deliver a clear answer in favor of the BEVs as well.

Outlook towards the efficiencies of the future

The technological development will tend to accelerate as well in the field of the BEVs and the production of e-fuels. As a result significantly better efficiencies of both technologies will occur. However there are certain physical limits as well as geographic conditions that the technological development will not erase. That’s why it will remain important to have a more differentiated view on mobility alternatives regarding their ecological impact. For society mobility and prosperity are closely linked. We will need any form of technology to assure our prosperity without sacrificing our climate. That’s why in the end there is no way around the use of alternative sustainable fuels such as e-fuels.